Reliability

Unique properties of ductile irone provide pipelines with:

- no corrosion in conjunction with high mechanical properties and functional features of spigot and socket connections;

- high safety margin compared to other pipeline sysems (Сmar <3,0);

- cold resistance (impact strength of ductile iron pipes does not change in the range from +20 Co to -60 Co)

Ductile iron pipes have less failure compared to pipelines of other materials.

Numerous tests have proven that along with the estimated permissible load ductile iron pipes have sufficient reserve reliability. It is ideal for complicated laying conditions.

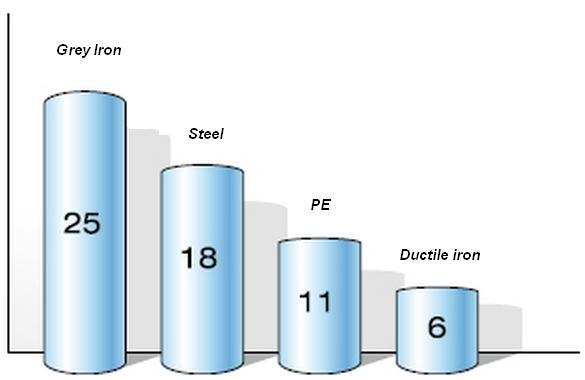

Number of failure per every 100 km of water pipelines. |

Water lines oservation of West Germany 1999 (Information given by Deutcher Verein des Gas Und Wasserfaches - German Water and Gas Providing Unity ) German Water and Gas Providing Unity gives the water pipe failure statistics (according to analyses more than 360 water service organizations, more than 126 000 km of potable water lines and about 5 million square km. of pipelines connected with living housing sector). According to the statistics, ductile iron pipes have the least percentage of failure. |

|

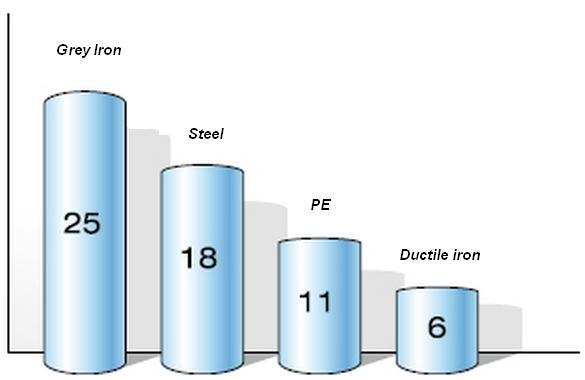

The data Pipe failure as a result of earthquakes in Japan, India and the USA (per 100 km) Spreading of water pipelines on the example of some earthquake prone areas of Japan, China, India and the USA (depend on pipe material) |

The statistics of pipeline failure during earthquakes on the territory of the USA, China and India 1989 - 2009 shows that ducile iron pipes in earthquake prone areas having the longest spreading have suffered less than other pipelines (4,4 failure per 100 km) from earthquakes more than 7 points Richter scale |

|

Moscow water pipeline failure statistics is practically the same(water lines spreading is more than 10 000 km; steel pipelines are 72%; 26% made of iron(1450 km - ductile iron); 2% polyethylene and concrete pipes) |

|

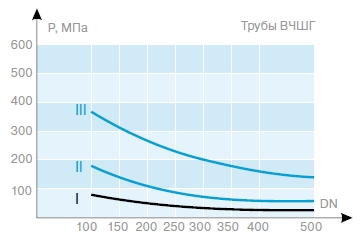

Ductile iron pipes and fittings have high margin level relating to maximum allowable pressure. The pressure level to break the pipe is more than maximum allowable rate. |

Sources of information:

- Japan Water Works Association « Damage to water Pipelines at the 1995 Hyogoken-Nanbu Earthquake».

- Iain Tromans Department of Civil and Environmental Engineering Imperial College of Science, Technology and Medicine London,« Behaviour of buried water supply pipelines in earthquake zones», January 2004.

- Kuraoka S., Rainer J.H.«Damage to water distribution system caused by the 1995 HyogoKen Nanbu earthquake» Canadian Journal of Civil Engineering, 23, (3), pp. 665-677, June 01, 1996.

- M. Nakano, S. Katagiri and S. Takada «Anexperimental study on the antiseismic performance of a U-PVC water supply pipeline with enlarged expansion joints» ASIAN JOURNAL OF CIVIL ENGINEERING (BUILDING AND HOUSING) VOL. 10, NO. 5 (2009).

- Eidinger, J. M. (1998). «Water Distribution System.» The Loma Prieta, California, Earthquake of October 17, 1989.

- Anil Kkumar Sinha, Senior Technical Advisor, Asian Disaster Reduction Center «THE GUJARAT EARTHQUAKE 2001».

- V. Thiruppugazh, Joint Chief Executive Officer Gujarat State Disaster Management Authority, India «WHAT HAS CHANGED AFTER GUJARAT EARTHQUAKE 2001».

- «DAMAGE BEHAVIOR OF LARGE-DIAMETER BURIED STEEL PIPELINES UNDER FAULT MOVEMENTS» LIU Ai-wen(1) , HU Yu-xian(1) , LI Xiaojun(1) , ZHAO Fen-xin(1) , TAKADA Shiro(2) (1. Institute of Geophysics, China Earthquake Administration, Beijing 100081, China; 2. Kobe University, Japan).

↑ наверх